PRODUCTS

DECANTERS

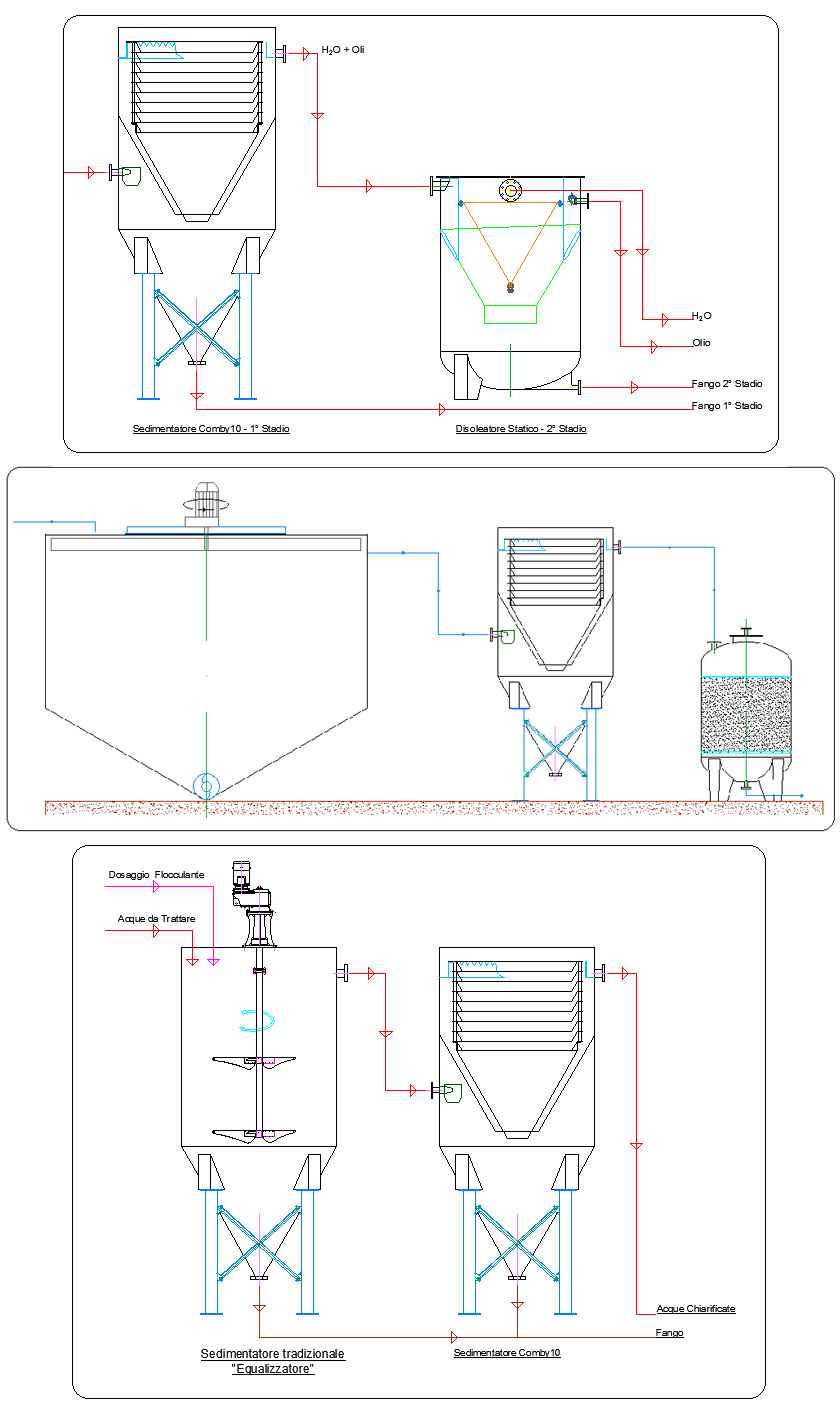

Comby 10 ® Decanter

The comby 10 ® system is designed to solve wastewater sedimentation problems while occupying less space than a conventional settler of equal performance.

APPLICATIONS

Thanks to its remarkable compactness and functionality, the Comby 10 ® series of modular decanters is best suited to chemical-physical plants that need to treat many m3/hour of flocculated or non-flocculated wastewater

- The most common applications are in the galvanic sector, paper industry, metal processing, marble quarries, textile industry, paint shops, but it is also suitable for sedimentation of any type of water containing wastewater with a specific weight greater than water.

- The COMBY 10 ®series can be implemented with the application of the oil and foam collection cone for an initial roughing of the oily parts in suspension.

- In order to obtain the correct sizing of the decanter, the necessary data is the sedimentation speed and the flow rate in m3/hour of effluent to be treated.

PRINCIPLE OF OPERATION AND USE

It is made entirely of GRP. (Glass Fibre Reinforced Plastic). It exploits the principles of gravitational, inclined plane and centrifugal settling, providing a useful surface area up to 10 times larger than the occupied surface area. It is assembled with modular elements that can be easily dismantled for maintenance, with no moving mechanical parts. It consists of a container with a conical bottom, resting on a steel frame, a hydrocyclone at the inlet, and a modular "cartridge" of 60 overlapping truncated cone elements.

The sedimentation process begins at the inlet with the centrifugal action of the hydrocyclone, separating the heavier particles; the liquid, with the other particles still suspended, is forced to descend towards the bottom of the container, where the medium-sized particles are compartmentalised by the action of a cone fixed to the cylinder. The lighter parts rise between successive inclined planes, separated by spacers, initiating sedimentation in a laminar regime in accordance with Stokes' law.

When the sludge particles deposited on the truncated cone surfaces reach a mass sufficient to overcome viscous friction and the various forces that hold it back, they slide down into the tank where they accumulate. The operating principle of the Comby 10 ® makes it usable as an intermediate stage between large decanters and sand or carbon filters, to increase efficiency. Various construction diameters are available in order to have capacities as close as possible to the needs of use.

We are available for quotations and further information.

TECHNICAL DATA: